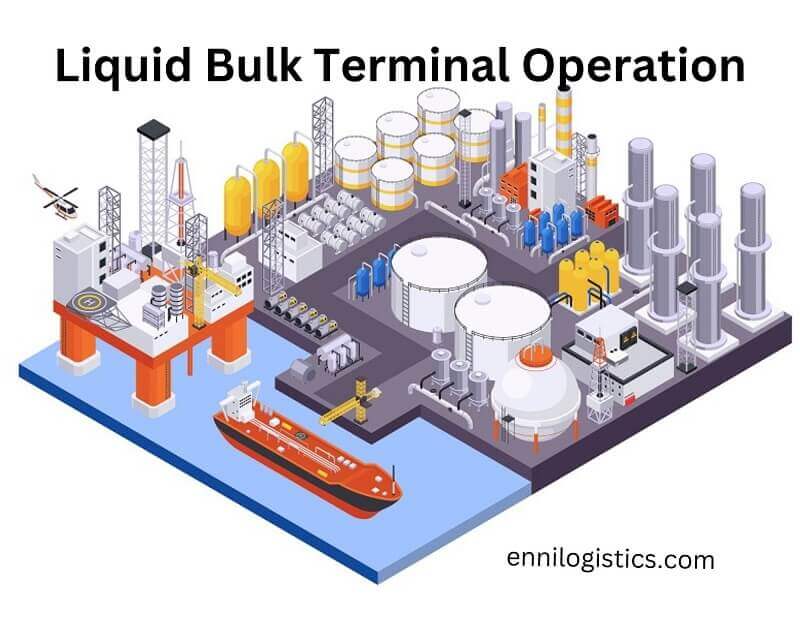

In the international shipping industry, liquid bulk cargo terminal operation is considered a challenging operation. Due to the risk and complex process of transfer and storage. Especially dangerous liquid cargo handling process is more complicated.

Here we are going to identify liquid bulk cargo terminal operation at a basic level.

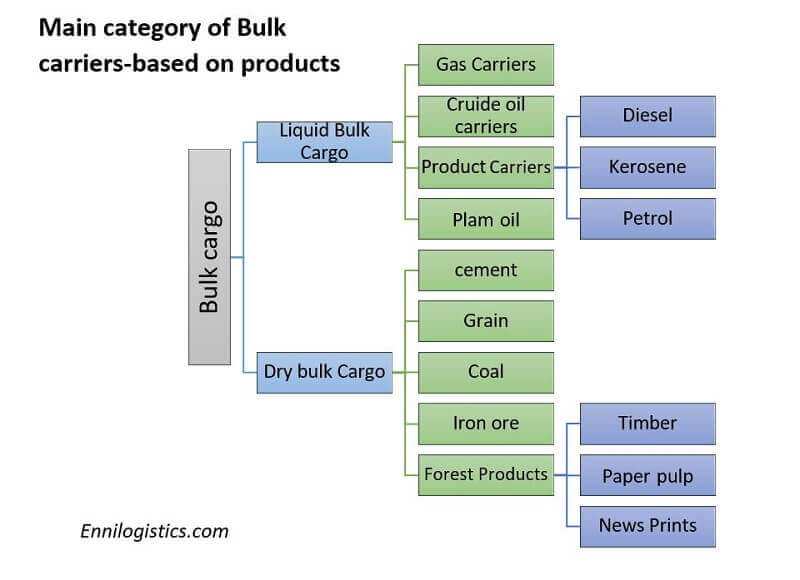

Before the explain liquid bulk cargo. It is useful to know the main types of bulk cargo and bulk cargo carriers.

Bulk cargo is divided into 2 main categories as liquid bulk cargo and Dry bulk cargo. Liquid cargo carriers vary with the type of liquid carried. There are different types of carriers. Such as

- Gass carriers

- Crude oil carriers

- Product carriers

- Plam Oil carriers

What is the Liquid bulk terminal?

When Liquid form cargo and gases form is transported by a liquid bulk terminal provides facilities for discharge and storage. Commonly liquid bulk terminal facilities were established for petroleum products, crude oil, LNG, and LPG.

Liquid bulk cargo Terminals

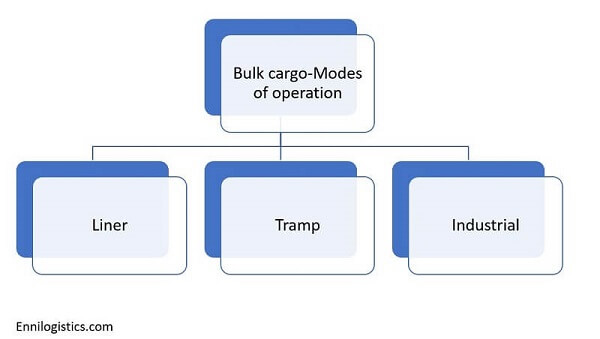

There are 3 types of liquid bulk terminals according to the mode of operation.

- Liner

- Tramp

- industrial

Next, we move on to the terminal operation process at the bulk cargo terminal.

Terminal operation at a bulk cargo terminal

- ship operation

- Quay transfer operation

- Storage operation

- Receipt and delivery operation

Indirect operation=ship operation+Quay transfer operation+Storage operation+Receipt and delivery operation

Direct operation=ship operation+Storage operation

For handling liquid cargo we need specified facilities at the terminal.

Facilities required for Liquid bulk terminal

- specialized berths/SPBM and terminals

- loading and unloading equipment-Pumps

- Quary transfer equipment -such as pumps, pipelines

- storage facilities

- refine and value-added facilities

- gate facilities for receipt delivery at the gate

- Fire and safety

- security

- emergency response

- ballast water treatment

What are Tankers?

Tankers are designed for carrying liquid bulk cargo.

example of carrying products

- crude oil or refined products

- liquid gas

- liquid wine

Load their cargo by gravity from the shore or shore pumps and discharge their own pumps

Currently, there are double hulls for the safety

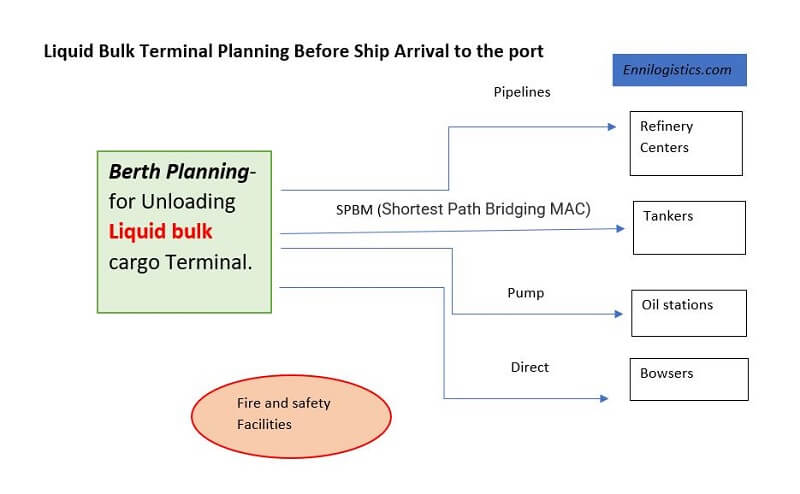

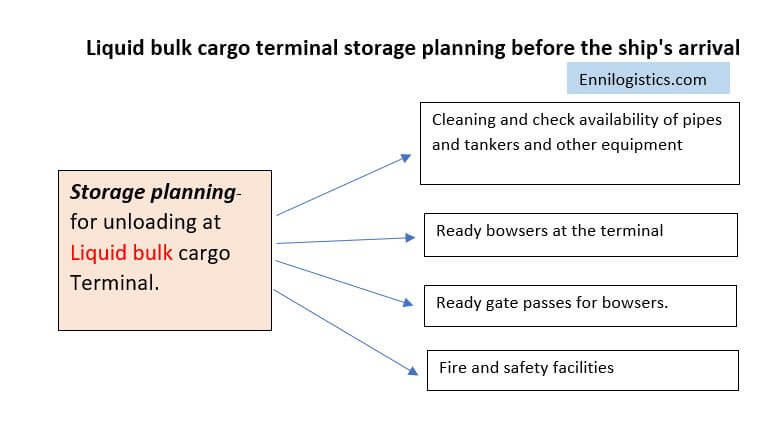

Liquid bulk cargo terminal planning before the ship’s arrival

Terminal planning is necessary to enhance efficiency and productivity at the port or terminal. Next, we are going to identify the liquid terminal planning process before the ship arrives at the relevant terminal.

Terminal operators receiving shipment arrival notices are to be aware of the estimated date of arrival of the (ETA ) ship or tanker.

Then terminal operators can pre-planning process. It is essential to do a pre-planning process according to the type of liquid the relevant tanker will receive.

Preplanning is very important to increase the efficiency of terminal operations and avoid congestion at the berth and terminal operations.

Unlike general cargo or containerized cargo, liquid cargo needs specialized facilities for unloading and storage delivery of goods.Because it is needed special conditions and requirements for operations.

For example, assume that a chemical bulk carrier arrives at a port. It is necessary to keep attention to fire and safety as well as emergency response facilities.

If it is dangerous cargo or a higher risk of fire cargo use SPBM in the sea which is out of the berth and transfer the liquid to tanks.

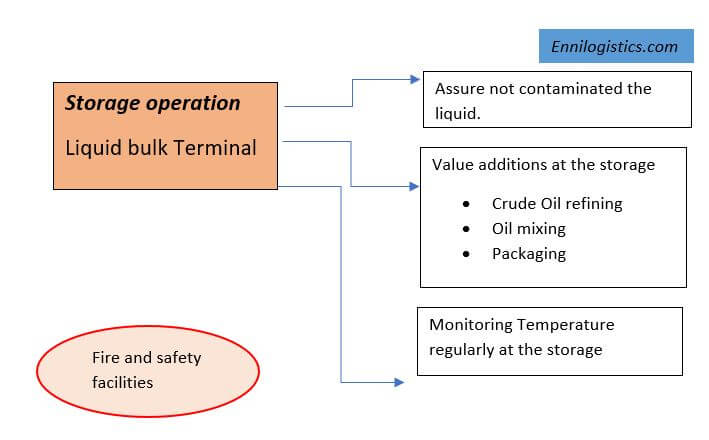

In the storage also need to pay attention to monitor the temperature regularly. Continuous monitoring is most important. Because some of the liquid types are flammable at the specific temperature level. Continuous monitoring and controlling can be avoided fire and damage. And also can be ready for immediate action in emergency situations.

Berth planning is the most important factor in liquid bulk cargo transportation at the terminal. It needs to check the availability of the relevant berth with matching the liquid bulk carrier or tankers requirements.

And also berth is should suitable for the unloading method of liquid. Such as if a plan is to unload the liquid cargo for browsers it needs to access of browsers at the terminal.if unloading the cargo through a pump to tanks needs required facilities for that process.

Required equipment and labor resource allocation are most important before the ship’s arrival at the berth.

Storage planning is a core process in liquid transportation at the terminal. Unlike general cargo liquid cargo in bulk can’t store in a yard or

any place.

liquid cargo can be stored out of terminal tanks, oil stations, or refinery centers.

In direct operations, the liquid cargo carrier unloads the cargo directly to browsers. This case not keeping stage facilities.it is required to provide facilities for browsers, needed to ready gate passes for browsers for quick operation.

Liquids are quickly contaminated with other liquids. To avoid contamination need to clean equipment, pumps, and storage properly.

Stand-by fire and safety facilities are a must in a liquid terminal. Because most of liquids are highly inflammable.

Human resources and other planning-Before ships arrive at the port

Same as the general ships arrive at the port, need to do advance proper planning of common things such as electricity and water supply of the ships,

Human resources planning,

mooring gang and mooring equipment

tug services and pilotage

Equipment for unloading liquid cargo-such as pump and pipelines availability checking etc

requirement supply for ship crew members-Foods, water, essential services

Staff ready for tally

staff and resources planning for the emergency response Fire brigade and security ensuring

Storage availability checking

CCTV and other continuous monitoring equipment

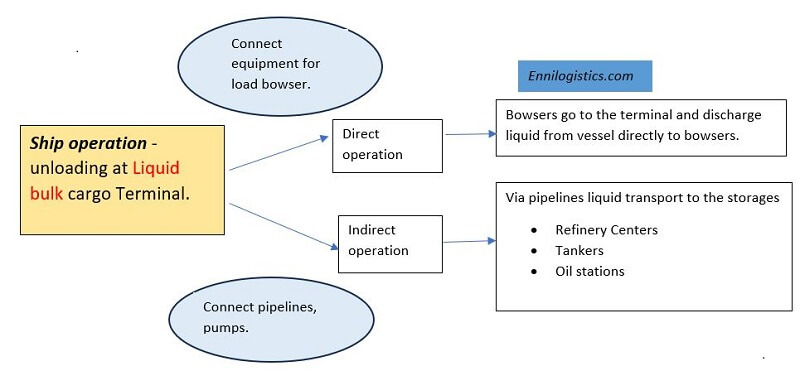

Ship operation- at liquid bulk cargo Terminal

for the ship, the operation process needs to provide electricity and water

The ship operation can be divided into two. As a direct operation and indirect operation.

Direct operation-connect equipment for unloading the liquid from the vessel and load to browsers. Then liquid cargo is directly loaded into browsers.

The smooth process of gate operation and receipt enhances the efficiency at the terminal.

Indirect operation- In this case, connect to pipelines and pumps transfer liquid to refinery centers, tankers, oil stations.

If liquid cargo is a chemical or highly flammable item unloading cargo using SPBM.

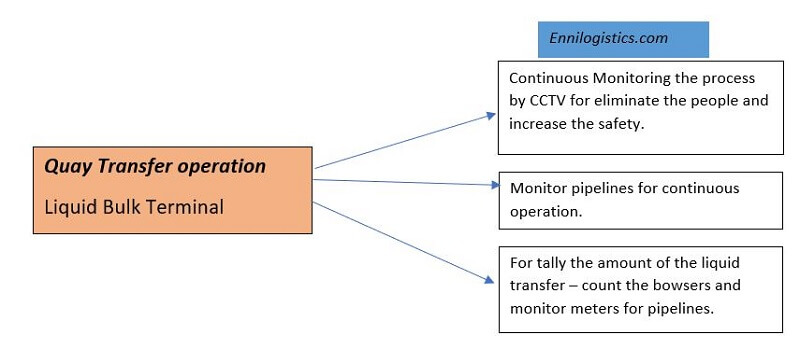

Quay transfer Operation-At liquid bulk cargo terminal

Quary transfer operation of liquid bulk cargo needs to monitor continuously.CCTV cameras and scanners help to monitor quay transfer operations.

Storage operation-At liquid bulk cargo operation

The most important thing is the storage not contaminated liquids. And also need to check the temperature because there is a higher risk of fire.

At the storage can value additions for raw liquid, such as,

- Crude oil refining

- Oil mixing

- packaging

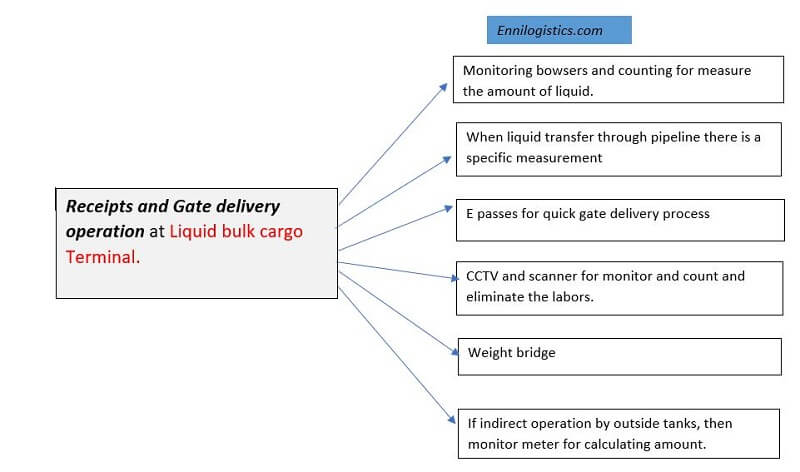

To measure the liquid amount, count the number of browsers in the direct operation

for increasing the efficiency of the gate operation

- Use E passes for browsers

- CCTV and Scanners use for counting and monitoring

- use weight bridges

When indirect operation of the liquid transferring process outside of the terminal tanks, monitor the meter and calculate the amount of liquid transferred.

FAQ

Liquid Bulk Cargo Terminal Operation: Everything You Need To Know

When Liquid form cargo and gases form is transported by a liquid bulk terminal provides facilities for discharge and storage. Commonly liquid bulk terminal facilities were established for petroleum products, crude oil, LNG, and LPG.

For more details, you can read Bulk and Breakbulk Terminal Design and Equipment

What is an example of liquid bulk?

- Different types of gases -LNG, LPG

- Crude oil

- Palm oil

- Diesel

- petrol

- kerosene

- Lubricants

- Sulphuric acid

- Adhesives

- Fruit juice

- Liquid fertilizer

What is the equipment used in liquid bulk cargo handling?

Electric systems–

- Cargo pump

- El-motor

- VFD (Frequency Converters)

- LCC (Local Control Cabinet)

- Bus communication to the vessel’s IAS system

Hydraulic systems

- Cargo pump

- Hydr-motor

- Hydr prop valves

- main HPU Hydraulic Powerpack Unit

- LCC (Local Control Cabinet) with Bus communication to the vessel’s IAS system

reference: https://www.pg-flowsolutions.com/

You may like to Read,

Ro-Ro Terminal Operation: Everything you need to know

How to save your money with Transshipment?

What is free port: Everything need to know

What is Demurrage? Detention / Laytime / Despatch

Port Charges and dues in Shipping Industry

Charter Party Contract In Shipping (Bareboat or demise/Voyage/Time)