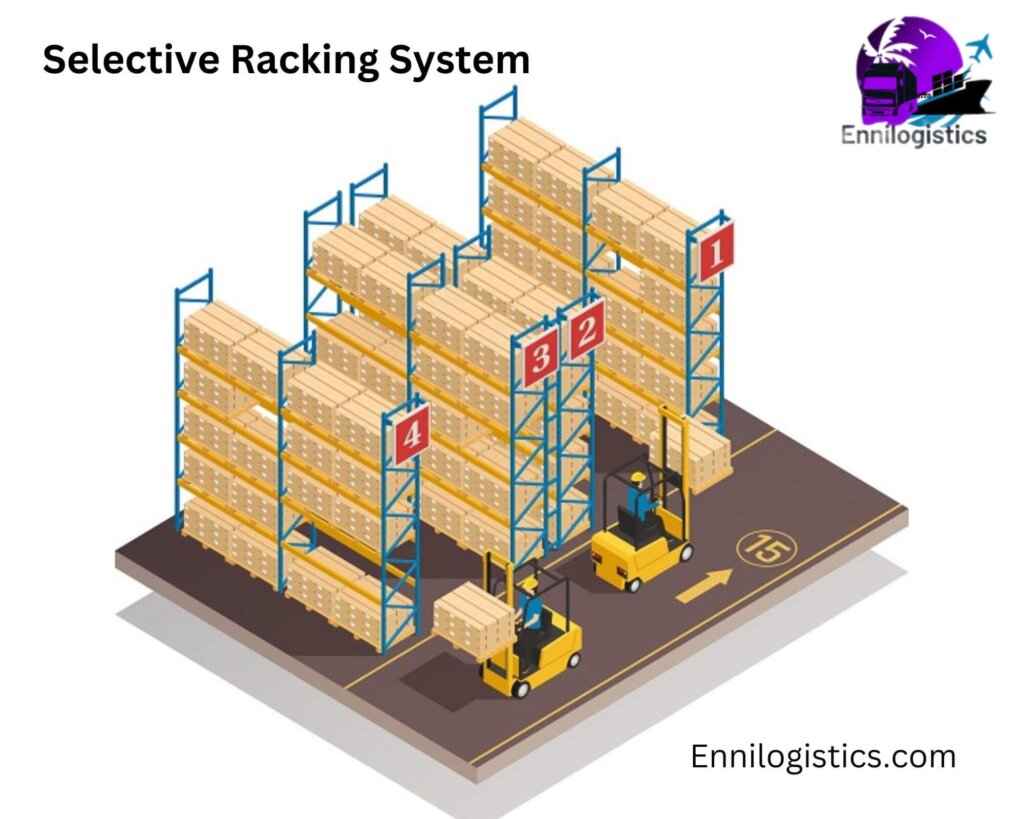

The selective racking system is the most popular and cost-effective pallet racking system used in warehouses.

Selective Racking systems

Also known as the selective pallet racking system. This type of racking system is designed for getting easy access to individual pallets or stock. It is a highly versatile storage method. The name “selective ‘ is used because this racking system has the ability to select and retrieve pallets or items without moving to other pallets. So pallets can be accessed individually.

Key features of the selective racking system

Accessibility– This racking system allows to access each and every pallet or stock individually. So picking, loading, and unloading is easy and it can be done without moving any other pallets. This does not disturb other pallets when loading, unloading, and picking.

Adjustability-designed with adjustable beams. when required to change the height of the pallets it is easy to adjust.

Space Efficiency– when compared to other pallet racking systems selective racking system is not a much space space-efficient system.

Inventory Rotation– use the “First In First Out” (FIFO) inventory rotation concept. This feature is most suitable for products having expiration dates due to spoilage.

Advantages of selective Racking system

- This racking system is able to store a variety of goods with different sizes and specifications.

- The rack is flexible so it can change according to product requirements. As a result of that warehouse storage capacity improving.

- Forklifts can reach each and every pallet easily. This increases transport and moving efficiency and convenience. With this racking system, there is a simple inventory management process.

- Selective racking system using warehouse no need to follow FIFO and LIFO methods, because forklifts able to access each and every pallet without disturbing others.

- The investment cost is lower than other storage systems.

- Increasing storage capacity

- Reducing product transport time at the warehouse

Not suitable situations for selective pallet racking

A selective racking system needs to occupy more than 30% of the space in a warehouse. So for storing a large amount of quantities of goods this racking system is not suitable.

Structure of a selective rack

There are 6 basic components as below,

- Upright frame

- Horizontal brace

- Load beams

- Pallet support

- Footplate

- Guard rail

Sourced by https://eurorack.vn/en/what-is-selective-racking.html

Videos Related to Selective Racking System

Selective Racking sellers in the world

Euro Rack Storage racking systems

REB Storage Systems International

Related posts you may like to Read,

FIFO, FEFO, LIFO: Best Strategies of Inventory Management

First Expiry, First Out (FEFO) concept

What is the First In First Out (FIFO) concept in Inventory Management?

Warehouse Management & Warehouse Management System: Everything you need to know

What is Logistics? Types of logistics,7 R’s, and more in a simple way of explanation

Main 3 Types of Logistics – Inbound, Outbound, Reverse

Reverse Logistics: Everything you need to know

What is Third party Logistics(3PL)?:Everything you need to know